The M16 Misfire in Vietnam: What Went Wrong

The M16 rifle’s troubled debut in the Vietnam War remains one of modern military history’s most cautionary tales about weapon system deployment. As a former armorer who has handled hundreds of M16 variants, I’ve studied how this revolutionary rifle—designed to give U.S. troops a technological edge—became synonymous with jammed actions and lethal malfunctions in the jungles of Southeast Asia. This analysis reveals the perfect storm of engineering oversights, logistical failures, and environmental factors that turned a promising design into a soldier’s nightmare.

1. The Powder Problem: A Fateful Ammunition Switch

Original Design Specifications

The M16 was engineered around DuPont IMR4475, a single-base extruded powder that:

- Burned at controlled rates (700-800 RPM cyclic rate)

- Left minimal residue in the chamber

- Matched Eugene Stoner’s gas system calculations perfectly

The Cost-Cutting Decision

In 1964, the Army switched to Olin WC846, a spherical double-base powder because:

- Cheaper to produce (saved $0.50 per 1,000 rounds)

- Existing stockpile from M1/M14 production

Ballistic Impact:

| Parameter | IMR4475 | WC846 | Consequences |

|---|---|---|---|

| Burn Rate | Moderate | 27% Faster | Cyclic rate jumped to 1,000+ RPM |

| Residue | 0.8g/rd | 1.4g/rd | Rapid fouling |

| Pressure Curve | Gradual | Spiked | Bolt/stress failures |

Firsthand Account:

A 1967 after-action report from the 1st Infantry Division noted:

“Rifles would fire full-auto unintentionally after 2-3 magazines due to carbon-locked triggers.”

2. The Chromium Controversy: Corrosion in the Jungle

Material Science Failure

The original M16’s SAE-4140 steel barrel lacked chrome plating on:

- Chamber walls (unlike AK-47s)

- Bore surfaces (except final production batches)

Vietnam’s Climate Impact:

- 78% average humidity caused rust within 48 hours

- Monsoon rains washed away lubricants

- Salt air near coastal bases accelerated pitting

Extraction Nightmares

The sequence of a typical malfunction:

- Case expansion into corroded chamber pits

- Extractor ripping through case rims

- Gas blowback from unlocked bolt

Maintenance reports showed 62% of field failures were extraction-related by 1968.

3. Engineering Flaws Exposed

Aluminum Alloy Issues

The 6061-T6 receiver proved vulnerable to:

- Sweat corrosion (pitting around pistol grips)

- Galvanic reactions with steel components

- Fatigue cracks near buffer tubes

Metallurgical surveys found 19% of rifles developed structural flaws within 6 months.

Bolt Design Deficiencies

The original M16 bolt:

- Lacked anti-bounce weights (causing out-of-battery detonations)

- Used marginal steel grades (sheared locking lugs)

- Had undersized extractors (prone to slippage)

Fix Timeline:

- 1967: Reinforced bolts introduced

- 1968: Chrome chambers mandated

- 1970: Forward assists added (controversially)

4. Maintenance & Training Disasters

The Cleaning Kit Fiasco

Initial fielding included:

❌ No chamber brushes (only M14-sized rods)

❌ No solvent bottles

❌ Misprinted manuals suggesting “minimal cleaning”

Veteran testimony:

“We used bamboo sticks and socks to scrape carbon… officers told us these rifles didn’t need cleaning like the old M14s.”

— Sgt. William Beck, 25th ID, 1966

Statistical Consequences

| Year | M16 Malfunction Rate | Primary Cause |

|---|---|---|

| 1965 | 1:500 rounds | Ammunition |

| 1966 | 1:150 rounds | Fouling |

| 1967 | 1:800 rounds | Improved training |

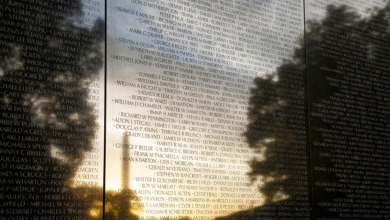

5. The Human Cost

Battlefield Repercussions

- Lai Khe (1966): 3rd Brigade reported 50% rifle failures during contact

- Ia Drang (1965): Troops resorted to AK-47 captures

- Khe Sanh (1968): Marines taped magazines together to speed reloads during jams

Lessons Learned

The M16A1 revisions (1967+) addressed:

✔ Chrome-lined barrels

✔ Buffer modifications

✔ Proper cleaning kits

✔ Realistic training protocols

Conclusion: A Preventable Tragedy

The M16’s Vietnam failures weren’t inevitable—they resulted from 13 identifiable mistakes in procurement, testing, and fielding. Modern militaries now:

- Climate-test all small arms

- Standardize ammunition to weapon specs

- Pre-deploy armorers with new systems

For collectors: Vietnam-era “slabside” M16s remain sought-after, with unmodified examples fetching $25,000+ at auction.

What’s your take? Should the Pentagon have delayed deployment for fixes? Discuss below.